This site

is mobile

responsive

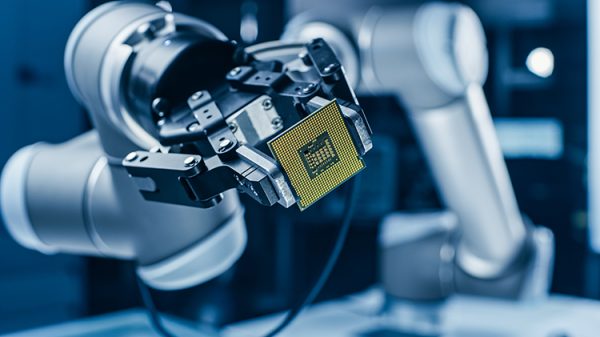

In today’s day and age, when companies want to stay ahead of the game, they need all technology systems to work synchronously. Systems that are not integrated results in significant increases in cost and resource consumption. Hence, system integrators (SI’s) play a significant role to support businesses.

These are specialists who are solution providers that address the pain points and fulfill the desired requirements of their customers, whether hardware, software or a system as a whole. In most cases, a system integrator integrates a system, into existing workspaces or machines, creating a brand new environment equipped with new functionalities.

The SI often brings to the table an understanding of mechanical, process and business intelligence issues and know how to integrate those disciplines into a working system.

Their inherent exposure to different industries results in a breadth of knowledge that comes from their involvement in various projects. System integrators learn to recognise that the experience gained in one application and industry can apply in another. This capacity allows them to explore innovative solutions to resolve a client’s challenges.

Most machines found today on production floors, particularly in the electrical and electronics (E&E) sector, lack connectivity between one another. This makes it difficult to extract relevant data to be turned into actionable insight. These legacy machines lack a connection port or a standard communication protocol which does not allow a connection to be established between one another.

It also presents as a hindrance for organisations to adopt Industry 4.0 as purchasing new machinery could still address the problem at hand although it requires significant investment from companies. Hence, an SI would prove essential to address such challenges of previous mode of operations.

An example of a Malaysian system integrator/solutions provider is Elliance, a company set up in 2011 to aid local industries to embark on Industry 4.0 motivation. Through their offering of the Optical Character Recognition (OCR) solution, engineers are able to extract data projected on the monitor screen and turn them into understandable information.

This solution makes data analytics possible and enables manufacturers to still utilise their legacy machines in their Industry 4.0 implementation.

The service solution by Elliance has opened up the possibility for many local companies to implement Industry 4.0 elements without having to replace the legacy machines on their production floor. They are, therefore, able to save millions of dollars while exponentially increasing their productivity and efficiency. Elliance has used the OCR solution to turn more than 500 legacy machines into Industry 4.0 – compliant machines in the country.

MIDA acknowledges the importance of system integrators in supporting the vision of Industry 4.0 in Malaysia and supports these SI companies, particularly local companies, to bolster their capabilities and capacity in the manufacturing and services supply chain. Among the facilitation provided is the offering of the Domestic Investment Strategic Fund (DISF) grant for research and development (R&D) or training initiatives. MIDA also connects local system integrators with manufacturing and services companies, allowing them to establish partnerships to embark on Industry 4.0 technologies.