This site

is mobile

responsive

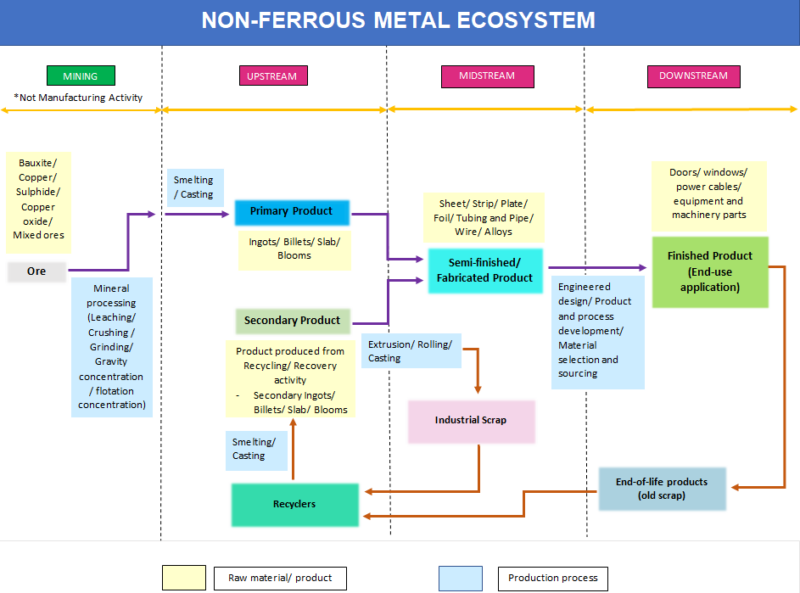

The increasing demand for renewable energy sources such as wind, hydro and solar power has led to a surge in demand for non-ferrous metals such as aluminium and copper which are mainly used in the production of electrical conductors; a critical component for renewable energy systems. This reflects the huge potential of the non-ferrous metals industry and its ecosystem in the future as it significantly supports the global shift towards sustainable practices in the manufacturing industry.

As of 2021, Malaysia boasts a roster of 89 licensed non-ferrous metal producers, collectively investing a substantial RM24.05 billion. In 2012, imports and exports of non-ferrous metals amounted to RM20.4 billion and RM10 billion respectively.

Having made good progress in developing Malaysia into a regional carbon services, there is a need to transcend into new opportunities in areas such as decarbonisation. Companies venturing into non-ferrous industries are advancing their technological skills, and at the same time, moving towards embracing Environmental, Social, and Governance (ESG) principles. There are two emerging trends, first, digitalisation and second, sustainability. We all need to work together to decarbonise and transit to a low-carbon future.

Termed the ‘Commodities of the Future,’ non-ferrous metals are set to shine due to global sustainability and digitisation demands. As copper and lithium are crucial for digital product production amid rapid digital transformation, this transition affects energy production, heightening demand for commodities like non-ferrous metals.

Challenges within the industry are being addressed in Malaysia, which has proven its resilience, even in the face of external shocks like the COVID-19 pandemic. The demand for non-ferrous metal products is expected to be significantly driven by the government’s commitment to developing the local electric vehicle (EV) system. Policies such as the Low Carbon Mobility Blueprint 2021-2030 and the National Energy Policy 2022-2040 underscore Malaysia’s push towards cutting-edge technologies and the subsequent heightened demand for non-ferrous metals.

The Malaysian Government remains steadfast in supporting this sector, introducing policies like enhanced recycling sector regulations and emphasising the importance of stronger industry associations to foster sustainable development and innovation.

In addition to the introduction of policies and regulations, MIDA is dedicated to facilitating companies that are considering future investments, whether in new ventures or diversification. Moreover, MIDA is actively engaged in enhancing the industry ecosystem to encourage collaboration among industry players.

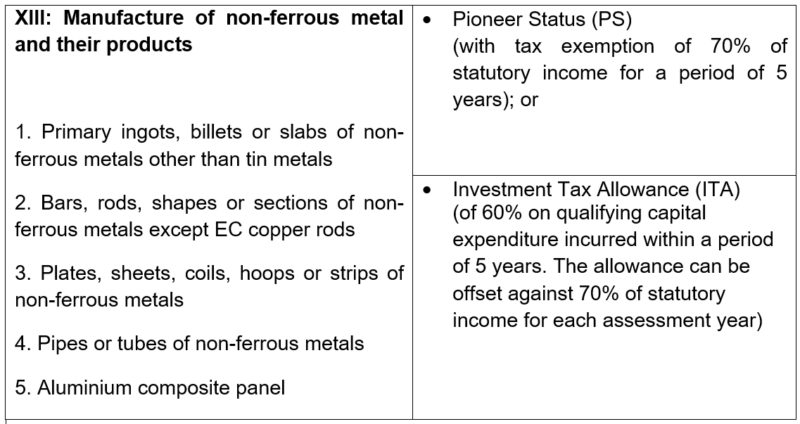

Facilitation by MIDA can be categorised into; granting approvals for investment projects and consideration for tax incentives:

*Note: Submission of Manufacturing License / ICA10 and Tax Incentive to be made through InvestMalaysia Online Portal: https://investmalaysia.mida.gov.my

Whilst aggressively promoting investments in the manufacturing and services sectors in Malaysia, MIDA is committed to build the nation in line with the National Investment Aspirations (NIA) outlined by the Ministry of Investment, Trade and Industry (MITI). This commitment involves integrating the NIA’s four key principles to foster the robust growth of the burgeoning non-ferrous metals industry, driven by escalating demand from sectors like automotive, construction, and electrical and electronics (E&E) sectors.

MIDA, in collaboration with MITI, is also actively shaping an ESG framework, slated for completion by 2024, to ensure sustainable industrial and economic progress in line with Malaysia’s aspiration to achieve carbon neutrality by 2050. As the non-ferrous metals sector, categorised as heavy industry, intersects with environmental concerns, this strategic approach assumes paramount importance in upholding ‘Green’ standards and fulfilling urgent global imperatives like addressing climate change through imperative ESG practices.

Moreover, the National Mineral Industry Transformation Plan 2021-2030 by the Ministry of Natural Resources, Environment and Climate Change (NRECC) seeks to efficiently manage Malaysia’s mineral industry, encompassing non-ferrous metals, to drive economic growth and establish the sector as a significant source of wealth within a decade, particularly focusing on strategic minerals. The framework is anticipated to pave the way for sustainable manufacturing technologies that mitigate environmental impact. MIDA, in collaboration with MITI and NRECC, is diligently refining mineral policies, including those related to non-ferrous metals, to harmonise and strategise the nation’s mineral development in synergy with other industries, thereby bolstering future technological trends and requirements.

The journey towards realising the full potential of the non-ferrous metals industry necessitates an unwavering commitment to continuous and strategic collaborations among all stakeholders involved. Recognising the challenges that lie ahead, it is through these collaborative efforts that we can surmount obstacles and pave the way for transformative change. This collective endeavour will not only propel the industry forward but also position Malaysia at the forefront of technological advancement, driving sustainable growth and innovation for years to come. To learn more, please contact Machinery and Metal Technology Division MIDA at https://www.mida.gov.my/staffdirectory/machinery-metal-technology-division/