This site

is mobile

responsive

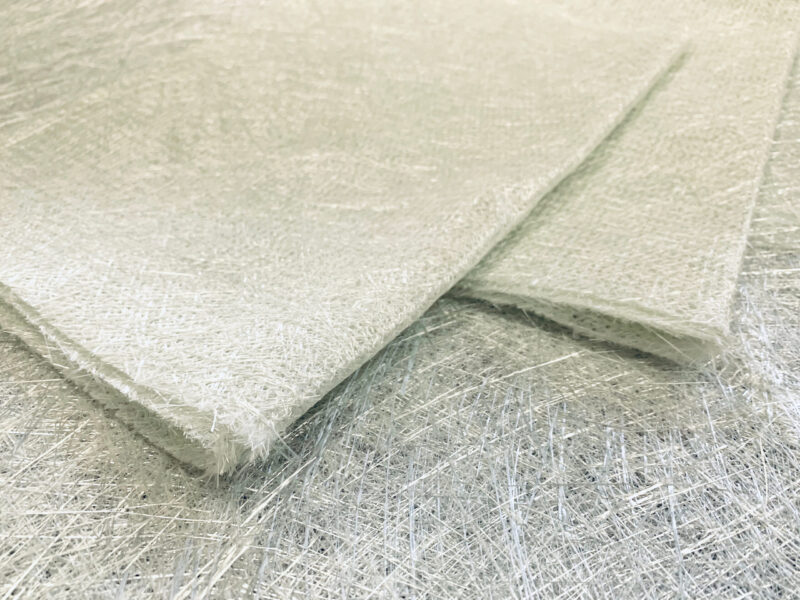

Fibreglass, or glass-reinforced plastic (GRP), is a composite material made of fine glass fibres embedded in a resin matrix. This combination produces a material that is both lightweight and incredibly strong. First developed in the 1930s, fibreglass has undergone significant advancements, evolving into a highly versatile solution for industries ranging from aerospace to construction, automotive and renewable energy.

The synergy of its core components which are glass fibres and resins, results in a material that performs exceptionally well under diverse stress conditions. Glass fibres offer tensile strength and durability, while resin ensures rigidity and resistance to moisture and chemicals.

One of the most compelling advantages of this composite is its high strength-to-weight ratio, which is crucial in sectors like aerospace, where reduced weight translates into better fuel efficiency and lower emissions.

Beyond strength, it offers exceptional resistance to corrosion, making it particularly valuable in the marine, oil and gas, and chemical processing sectors. Unlike metal, it does not rust or degrade when exposed to moisture, salt, or chemicals, which makes it suitable for application in the oil and gas sector.

Due to its low thermal conductivity and non-conductive properties, fibreglass serves as an excellent insulator. It is increasingly used in electrical housings, high-voltage environments, and thermal barriers, where heat resistance and electrical safety are crucial.

To date, Malaysia has attracted RM5.2 billion of investment in the fibreglass industry. At the moment, the only upstream player in Malaysia’s fibreglass ecosystem is Nippon Electric Glass (M) Sdn. Bhd., a subsidiary of Nippon Electric Glass Co., Ltd. (Japan). The company produce glass fibre in chopped strand and roving form to cater for diverse industries globally since 1998.

On the downstream side, 38 companies are active in manufacturing fibreglass products for use in the automotive, construction, maritime, and oil & gas sectors. Among them, CRT Manufacturing Sdn. Bhd., established in 2019, has made a name for itself with eco-friendly construction materials, including non-metallic fibreglass rebar—a game-changing alternative to steel reinforcement.

The global movement towards sustainability underpins the wider acceptance of fibreglass. Its longevity, resource-efficient production methods and recyclability potential position it as a compelling alternative for conventional materials and a “green alternative”. Fibreglass is playing an increasingly significant role in Malaysia’s industrial landscape, a trend that strongly supports the ambitions of the New Industrial Master Plan 2030 (NIMP 2030).

The plan’s emphasis on advanced materials and enhanced local manufacturing is directly addressed by the growing demand for fibreglass in the various sectors. As demand rises for robust and sustainable infrastructure, domestic production and innovation in this field are set to increase, generating skilled employment and driving technological advancement.

Electric Vehicles (EVs): The EV sector is central to NIMP 2030, and lightweight materials like fibreglass are essential for EV design. Malaysian fibreglass producers are well-positioned to supply components for this rapidly growing industry, both domestically and internationally.

Construction: Fibreglass is increasingly being adopted as a sustainable and efficient alternative to traditional materials like steel and concrete in construction, offering benefits such as lower lifecycle costs, recyclability, and greater design flexibility for complex structures. Companies like CRT Manufacturing Sdn. Bhd. are already making strides with eco-friendly fibreglass rebar. With continued commitment of the industry players and support from Government policies, fibreglass is well-positioned to play a crucial role in the future of eco-friendly building in Malaysia.

Oil & Gas: Fibreglass (GRP) tanks and piping systems offer superior longevity and lower maintenance costs compared to traditional materials in the oil and gas sector, boosting operational efficiency. Its resistance to corrosion makes it particularly valuable in these environments. Its inherent longevity, resource-efficient production methods, and recyclability potential have positioned fibreglass as a compelling substitute for conventional materials.

Aerospace: Fibreglass’s high strength-to-weight ratio is crucial in aerospace for better fuel efficiency and lower emissions.

Electrical and Thermal Insulation: Its low thermal conductivity and non-conductive properties make it an excellent insulator for electrical housings, high-voltage environments, and thermal barriers.

Malaysia holds all the right cards to become a regional hub for fibreglass manufacturing and innovation. Through government agencies like MIDA, Malaysia offers investment incentives and facilitations that support high-value industries. Fibreglass, sitting at the crossroads of sustainability and industrial utility, stands to benefit immensely.

As industries globally evolve towards sustainable, high-performance, and cost-efficient solutions, fibreglass has moved beyond being a mere alternative to becoming a cornerstone material for modern industrial development. From constructing resilient bridges to the manufacturing of electric vehicles (EVs), and reinforcing cement to insulating high-voltage systems, fibreglass is shaping the future of industrial applications. Malaysia, with its strategic industrial goals, supportive ecosystem, and pioneering industry players, is poised to drive this transformation.

MIDA recognises fibreglass as a future preferred material for industrial applications. Investors are encouraged to further explore the promising investment opportunities offered by this high-potential material by engaging with the dedicated team from the Building Technology and Lifestyle Division at https://www.mida.gov.my/staffdirectory/building-technology-lifestyle-division/.