This site

is mobile

responsive

Since the outbreak of the pandemic, global business and manufacturing ecosystems have been upended, reinforcing the urgency for automation as governments and business leaders focus on reinvigorating the languishing economy. The pandemic has revealed how vulnerable global supply chains can be and has motivated manufacturers to rethink automation adoption in a more cost-effective manner, especially in the areas of customer engagement, supply chain, production and operation strategies. Adopting automation for cost-effective technology solutions is now critical for businesses to thrive in the post-pandemic economy.

Automation is capable of greatly improving the efficiency of manufacturing operations and at the same time, reducing costs.

It also allows a single facility to produce a variety of products and boost output (ie. a machine capable of packing a large number of units per minute or hour can improve a company’s bottom line). The global industrial automation market size was valued at USD168.81 billion in 2019 and is projected to reach USD326.14 billion by 2027, at a forecast CAGR of 8.9 per cent.[1]

In 2020, the World Economic Forum (WEF) published a report revealing the rise of machines and automation that would eliminate 85 million jobs by 2025, however WEF also expects 97 million new jobs will be created. With a focus on job creation, efforts towards rationalising automation and digitalisation is a critical progressive move forward. [2]

On one hand, this helps businesses effectively use their resources and on the other hand, it also equips their manpower with capability to improve productivity, technology deployment and speed. Hence, automation helps to not only achieve cost-competitiveness, but also ensure the current workforce remains relevant in targeted highly skilled and higher income job segments, in line with the country’s move towards a high income economy.

Currently, the state of the industrial revolution in Malaysia’s manufacturing sector is between Industry 2.0 and 3.0; and is predominantly made up of Small Medium-Sized Enterprises (SMEs). Given that SMEs contribute approximately 38% to the Malaysia GDP (in 2018) and 59% to the total employment, it is a crisis for the nation if SMEs remains unaware of the importance to embrace automation to improve their manufacturing competitiveness in future pandemic-related lockdowns and post-pandemic period.

The lack of understanding about automation technologies and the high cost of equipment are two common challenges cited by companies specifically SMEs. One of the biggest misconceptions is the high cost of adopting automation technology and that they have to automate their entire production line.

In order to address the issues, companies should first identify the specific processes in their production lines that can be improved through automation or companies could start with simple devices to enable data collection/ analytics and gradually enhance to highly sophisticated machinery and equipment that is adaptable to artificial intelligence and other Indusry4wrd technology.

Among the Government initiatives to encourage smart manufacturing is the Industry4wrd policy. This framework includes three core elements and eight core thrusts designed to create a pathway for enhanced productivity, job creation, and to grow a high-skilled talent pool in the manufacturing sector.

Malaysia Factory Automation Providers/ System Integrators

Get help from the experts

In today’s day and age, when companies want to stay ahead of the game they need their systems to work synchronously. Systems that are not integrated result in significant increases in cost and resource consumption. Integrated systems are important because the process can boost the speed of information flows and reduce operational costs.

There are always tradeoffs when considering the level of automation for a facility, but the critical factor is to have the experts at the table very early in the process and to carefully consider all options. In order to materialise the success of the automation journey, companies should identify and work with factory automation providers/system integrators (SI). These experts play a significant role in bringing systems, equipment, and machinery together to create a manufacturing solution while enabling the business to improve its productivity and quality of operations. Their inherent exposure to different industries results in a wide breadth of knowledge that comes from their involvement in various projects. The experience gained in one application and industry can be applied in another. This capacity allows SIs to explore innovative solutions to resolve a client’s challenges.

In Malaysia, there are about 50 companies including Malaysianowned companies that have grown and established themselves as internationally recognised providers of factory automation systems such as Pentamaster, ACM, Greatech Integration, Genetec, Cheng Hua, TXMR, Vepro and XTS Technologies.

Each of these reputable companies is well-known for its unique capabilities and specialities which allow them to serve in both local and global markets.

In 2010, there were about 25 local factory automation companies in Malaysia, with a total market value of merely RM234 million.

Today, more than 50 factory automation companies are operating, with the top 10 companies having an accumulated total market value of more than RM25 billion.

They provide different kinds of solution that is required by the customers, as shown:

While different companies require different solutions when it comes to automation, even within the same industry, there are varying challenges to automation. It is critical to find a factory automation provider/system integrator on this journey who can offer the right support to enable a smoother journey. Through its engagements with SMEs and multinational corporations, MIDA can assist to connect the companies with factory automation providers/system integrators as well.

Automation Project Initiatives (API)

As a testament to MIDA’s commitment in supporting automation within the manufacturing sector, the Automation Project Initiatives (API) was launched. This programme focused on enabling Malaysian businesses to adapt to the new normal in the post-pandemic era. MIDA’s API is a physical platform that serves to connect labour intensive/low productivity companies with potential system integrators/factory automation players.

In short, the objectives are:

Since its commencement on 15 September 2020, MIDA has organised a series of API programmes with the E&E sector and business associations, namely the Timber Association. Several webinars on Government Facilitation for companies undertaking automation and digitalisation initiatives with reputable Malaysian factory automation providers/system integrators such as XTS Technologies Sdn. Bhd. and TXMR Sdn. Bhd. were also held. These initiatives aim to promote the importance of automation among local companies to transform their facilities towards becoming more competitive and cost effective while ensuring the success of their automation journey in Malaysia.

API is an ongoing project and MIDA encourages interested companies to contact the Machinery & Metal Technology Division for more information.

Government Support and Facilitation

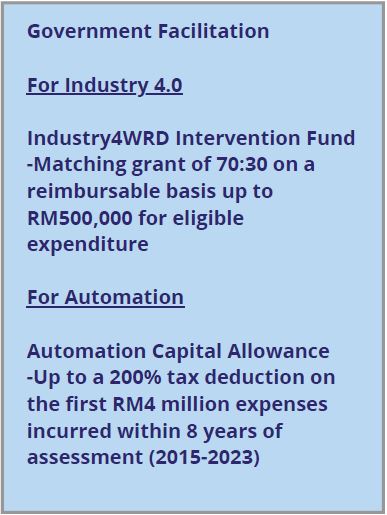

Among the initiatives to encourage this paradigm shift include Malaysia’s Industry4WRD policy which serves as an excellent guide. Through its Industry4WRD Readiness Assessment and the subsequent Intervention Fund, the Government is committed to assist businesses in:

Companies, including SMEs are encouraged to leverage on the initiatives and facilities offered to local companies to move towards Industry 4.0 and automation.

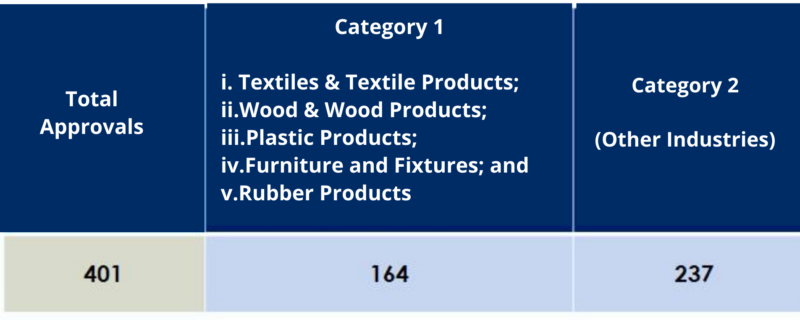

As of April 2021, MIDA has approved 401 applications for the automation capital

allowance as shown in table above.

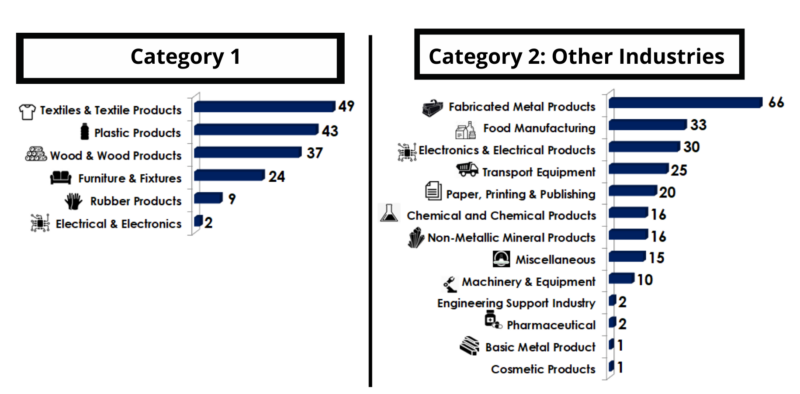

Breakdown of Automation CA approval by industries

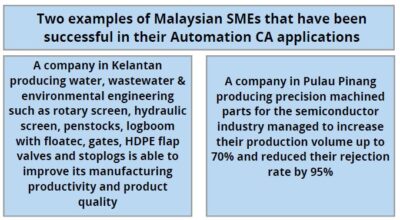

Companies that have leveraged on these facilities have experienced tangible benefits of automation. Based on the impact analysis of 245 projects approved as of March 2021, these companies have invested more than RM583 million in automation, machinery and equipment. These findings signify that automation is inevitable for business sustainability.

As a result of these investments, companies reported cost savings due to the reduction of over 2,089 unskilled workers and contributed an average of 203.31% improvement in production volume.

Special Tax Incentives Under PENJANA

For new and existing companies that are planning to relocate or incur new investment, the Government has provided a special tax facility.

Under PENJANA, a 0% special tax rate for 10 years for new investments is offered to new companies in the manufacturing sector that has capital investment between RM300 million to RM500 million. Meanwhile, existing companies in Malaysia that are relocating their overseas facilities into the country with a capital investment of above RM300 million may apply for 0% Investment Tax Allowance (ITA) for 5 years. This allowance is offset against 100% of their statutory income for each assessment year.

Transforming Investment Facilitation

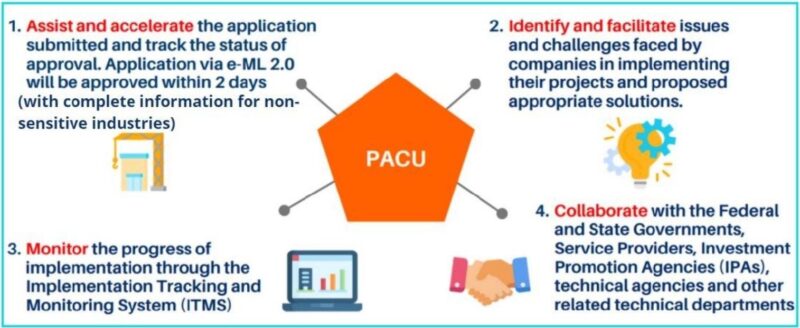

MIDA has also established a Project Acceleration and Coordination Unit (PACU) to facilitate all necessary approvals.

This is in addition to the presence of the 12 MIDA state offices to assist and facilitate investors who are not based in Kuala Lumpur, namely in Selangor, Perak, Pulau Pinang, Kedah, Terengganu, Kelantan, Pahang, Johor, Melaka, Negeri Sembilan, Sabah and Sarawak.

MIDA acknowledges the importance of factory automation providers/system integrators in supporting the vision of Industry 4.0 in Malaysia and support these factory automation providers/system integrators companies, particularly local companies, to bolster their capabilities and capacity in the manufacturing and services supply chain. The post-pandemic environment will undoubtedly continue with disruptions and volatility.

In order to survive and remain competitive, it is vital that digital manufacturing be incorporated into the business roadmap.

This will serve as a sustainable long-term growth strategy and enable them to compete in the global market.

Companies who are interested to connect with factory automation providers/system integrators players, contact MIDA today!

Source: MIDA e-Newsletter August 2021