This site

is mobile

responsive

Malaysia is one of the top producers of fossil fuel plastic product, with the sales turnover of RM48.46 billion and RM13.3 billion export in the year 2020 (Malaysian Plastics Manufacturers Association Annual Report 2020). In view of how significant we are in benefitting economically versus how much we consume, are we doing enough to address the challenges that come along?

The recycling rate in Malaysia was at 28.1% in 2019 and was predicted to achieve 40% in 2025. However, not all plastic products can be recycled. Some of it is disregarded by the waste collectors because of various factors such as hazardous or economic reasons. The Malaysian Government and NGOs have launched several awareness campaigns and have established the ‘Malaysia’s Roadmap Towards Zero-Single Use Plastics 2018 2030’.

The vision of the Roadmap is to take a phased, evidence-based and holistic approach by involving all stakeholders in jointly addressing single-use plastics pollution in Malaysia. The Roadmap is envisaged to deploy actions that can deflect the current trajectory to a more sustainable pathway thus establishing a more circular, cleaner and healthier environment by 2030.

Based on the current scenario, the consumers are blaming companies for being unable to supply environmental-friendly products, while the producers are putting back the responsibility on consumers for failing to recycle due to a lack of awareness. Some argue that recycling is a lobbying campaign that serves as a “guilt eraser” for concerned customers, allowing them to continue to ignore the problem.

We need to do more than recycling. It must start with a redesign of business models whereby all products manufactured are easily recyclable, repurposed, or reused utilising sustainable sources of raw materials. This may also apply to designing parts or component that can be easily disassembled, reassembled and retrofitted.

The circular economy is based on the principles of designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. Until then, it will be recycled as raw materials for new products. The aim is to let the products continue to circulate as long as they can and minimise the use of virgin materials to produce new products.

If we still remember those days where people collect glass bottles from house to house and sell it to the recycling centre where they clean, sterilise and supply them back to the food manufacturer, we were in fact circular back then. In comparison, most glass bottles are thrown without much thought these days and only some are separated at the collection site and crushed as raw materials.

As part of a sustainable drive to foster a circular economy, companies are urged to implement a ‘buyback programme’. Brand owners must take responsibility for their product waste such as electronic/electric waste, automotive parts waste, water bottles, cooking oil bottles and plastic containers. The collector can then be compensated with a fair price as an incentive.

Nonetheless, the circular economy does not just revolve around plastic. It is about setting up new business models that must be looked at as business opportunities. Raw materials are running out as we are consuming more than what the world can produce. By circulating the goods, it is as good as securing your future raw materials (by keeping them in the loop) with minimal dependence on virgin materials which have fluctuating prices.

Circular BioEconomy

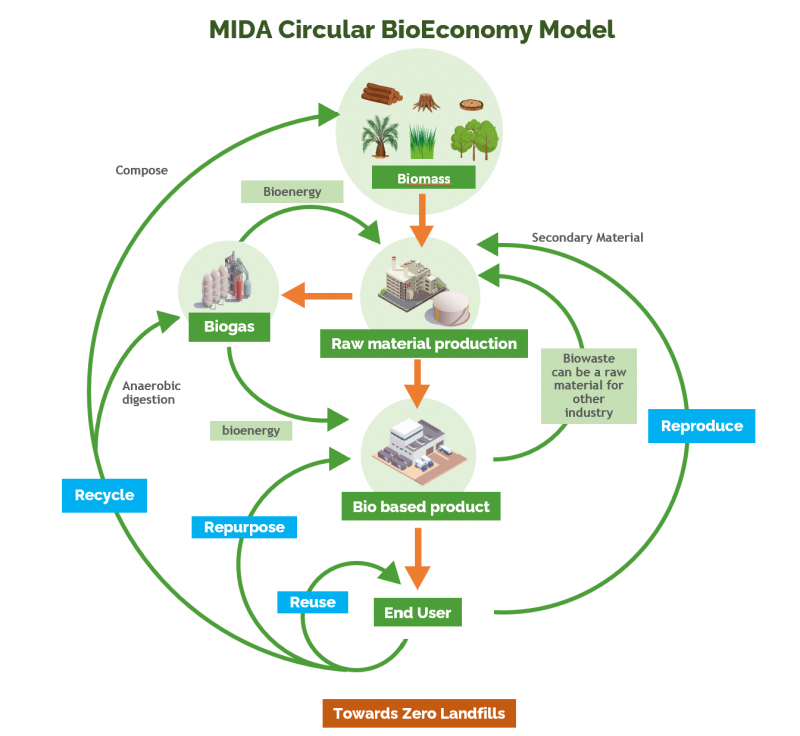

Circular bioeconomy is an area that is worth looking into when it comes to addressing the issue. A bio-based economy will be a reasonable solution to the world’s problem, which is climate change. Circular bioeconomy is based on nature as a source. The source is mainly biomass which is a renewable source that is massively available in Malaysia. A biobased source work in harmony with nature such as bioplastic bottles made from PLA based on “plant base oil” as it can dissolve naturally in a normal environment, be it at land, sea, or water.

According to various studies, fossilbased fuel is estimated to last for just another 50 years. As such, the Sarawak State Government is vigorously exploring a new form of biobased solutions such as biofuel, biochemical, green hydrogen and algae. The goal is to gradually phase out fossil-based plastic and replace it with renewable materials that can be reproduced sustainably.

International bioplastic manufacturing companies are producing biodegradable plastic that is made from plant-based oil, serving the sustainable plastic demand in the US and Europe. There will be an increasing demand for business opportunities in this area as the market grows and regulations are tightened.

The good news is that the resin produced can be used as a dropin raw material to the existing plastic moulding machine without much modification. But until the price becomes more competitive, fossil-based raw materials will still be the choice of the producer and consumer.

Some of us are looking to other countries when it comes to developing a climate solution, but unknowingly, other countries are looking at Malaysia as a new source of bioresources. Malaysia has an abundant feedstock with an estimate of up to 25 million tonnes of biomass to be utilised.

This has attracted the attention of notable biobased companies around the world. MIDA seeks to leverage this opportunity and welcomes the right partners with suitable technologies to make Malaysia their next investment destination. The focus is now for Malaysia to be more optimistic and move into producing a higher-value biobased product rather than just exporting the raw feedstock or materials.

A circular bioeconomy is a possible way to address the waste issue as it is circular in nature. All stakeholders need to take a step back and look into what Malaysia does best, improve the system and technology so that the valorisation of the product is optimum. Since Malaysia is blessed with agricultural resources, the focus is now on ensuring resourceefficient valorisation of biomass by focusing more on establishing sustainable biomass projects through Integrated Biohub and Biorefineries of the future.

Which is the best path forward for Malaysia? Circular economy or leapfrog to Circular Bioeconomy. For more information, contact the Circular Bioeconomy Unit of MIDA (https://www.mida.gov.my/staffdirectory/circular-bioeconomy-unit/)

Source: MIDA e-Newsletter May 2021