This site

is mobile

responsive

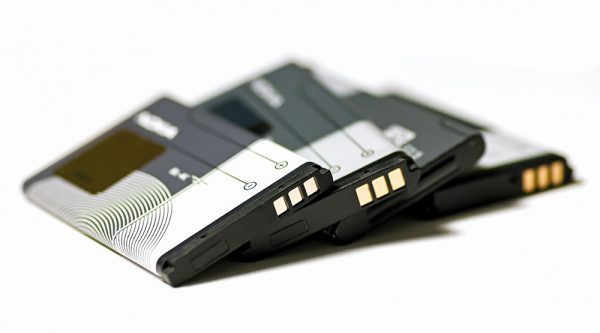

The first successfully produced synthetic gemstone was a ruby made in 1902 by Auguste Victor Louis Verneuil. The Verneuil Technique enabled the production of gemstones of high quality to be used for making of jewellery. Since then, the method has been expanded to other gems, with manufacturers utilising laboratory-synthesised sapphires for a variety of industrial and decorative purposes. These synthetic sapphires are used in optical lenses, semiconductors, light-emitting diodes (LEDs), artificial sapphire glass (e.g. mobile phone and television screens), medical devices, aerospace, lithium batteries and power storage components.

Its remarkable hardness drives the versatility of sapphires. Made from corundum and being a nine on the Mohs scale, sapphires are harder than topaz and triumphed only by diamonds. They are comparable to titanium carbide and are ten times stronger than stainless steel. Sapphires are also almost totally scratch and thermal shock resistant.

While natural sapphires have different appearance and quality depending on its place of origin, synthetic sapphires, scientifically known as crystalline alumina, are close to colourless. This is mainly due to the near absence of metal contamination during its formation process. The main ingredient of producing high-quality synthetic sapphires is high purity alumina (HPA).

With the increasing adoption of technological advancements, the global market demand for synthetic sapphires and HPA are also expected to grow year on year. Synthetic sapphire will lead to the future of technological growth. Recognising the potential of this industry, the Government, through the Malaysian Investment Development Authority (MIDA) has been promoting high purity alumina under the Promotion of Investment Act (PIA) 1986.

MIDA has approved one manufacturing project with investments of over RM1 billion in Tanjung Langsat, Johor to produce HPA using a proven and robust chemical process called hydrochloric acid leach or HCL.

This process is cost-effective, reduces the impurities in the final product and is also environmentally friendly. The company is capable of producing HPA of the highest purity level at 99.99% (4N) purity.

Leveraging on targeted ecosystem approach, MIDA is intensifying its efforts to entice more players in this technologically advanced industry. Promotional and awareness programmes are continually put in place to achieve the end goal – making Malaysia the preferred destination for the manufacturing of synthetic sapphires and HPA.