This site

is mobile

responsive

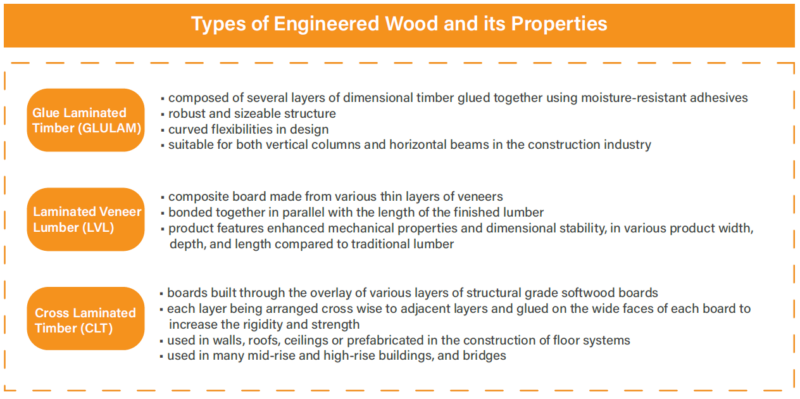

The global push for sustainable and eco-friendly practices has driven the wood products industry to innovate and adapt new applications to remain relevant. One segment of the wood industry that has immense potential to leverage on the concerted call for environment conservation is the engineered wood industry. As an advanced alternative to conventional lumber, the versatile and sustainable engineered wood industry is poised to revolutionise the construction industry. Engineered wood presents a new class of building products and materials. While metals and plastics replaced wood in the past, wood may now replace these materials due to highly improved performance and desired availability for the construction sector. Engineered wood materials have been found to be cost-competitive as an alternative to concrete structures especially for buildings higher than six stories.

Contrary to traditional wood products that are often linked to deforestation and environmental degradation, the engineered wood is created by bonding wood fibers, particles, or veneers to form a durable and strong material while minimising waste and utilising sustainable sources.

Globally, the engineered wood market continues to record significant growth. Indirectly, the growing engineered wood-based panel production has increased the global wood adhesives market size which reached approximately USD7.03 billion in 2023. The adhesive market which is crucial for the engineered wood products’ long-term stability is estimated to grow at a compound annual growth rate (CAGR) of 8.6% from 2024 to 2030.1 Furthermore, demands in the construction sector post pandemic has accelerated consumption of engineered wood particularly LVL. Countries such as Germany have higher consumption of LVL through the increase of timber frame share in building methods. Similarly, the usage of GLULAM has been on a spike in Austria.2

● Global market for CLT to grow at CAGR of 14.6% reaching USD 5.03 billion in 2032 ;3

● Total EU consumption of LVL grew from 170,000m3 in 2007 to 375,000m3 in 2017

Malaysia’s wood products industry has been transforming progressively from a primary product exporter to higher value-added product exporter over the past three decades. Similar to the global trend, the engineered wood industry in Malaysia is also experiencing a growing consumption by the local construction and manufacturing sectors. The Malaysian Timber Industry Board (MTIB) reported that the wood-based manufacturing sector in the country, recorded increased exports reaching RM25.28 billion in 2022. Although the engineered wood products require extensive tropical timber composite product analysis, research and technology, Malaysian based companies in premium medium and high-density fibreboard (MDF and HDF) segments has adopted technology enhancement in their operations.

One of the notable local players that has been operating for more than 20 years in Mentakab, Pahang is Robina Flooring Sdn. Bhd. Motivated by its production capacity of 5 million m2 annually, Robina Flooring Sdn. Bhd. is distinguished in its niche, manufacturing laminated flooring products which are exported to 52 countries. The company invested in automated press machines that enable them to deliver cutting-edge, high quality laminated flooring, meeting international standards. Its commitment in adapting tropical High Density Fiberboard (HDF) with European-origin veneer and paper components with detailed production performance creates a comparative advantage to its products.

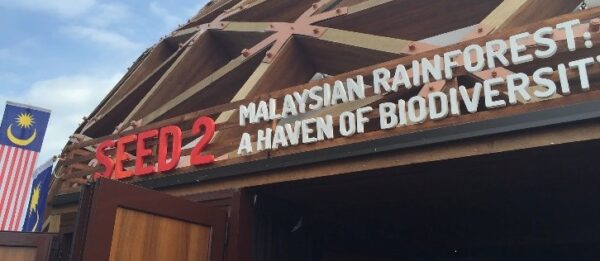

Another success story originates in the southern state of Johor. Woodsfield Group of Companies, established since 1998, has been growing exponentially from providing railway sleepers, hardwood timber, wooden blocks and finger-jointed timber (non-structural) to becoming Malaysia’s first company to introduce GLULAM technology in 2009. Its effort to promote GLULAM tropical wood as a sustainable, versatile and stable construction material was showcased though its unique design of the MALAYSIA PAVILLION in MILAN, ITALY during the Milano Expo in 2015.

The company’s vision to push forward new limits and to consistently provide high standards of products through collaboration with leading testing and research institutions in Europe led to its success in obtaining the first Tropical Hardwood Glue-laminated Certification for its Glue-laminated Keruing timber.

In Selangor, joining the existing arena is Weng Meng Greentech. Established in 2022, rising from decades of Weng Meng Group of Companies’ timber doors and cable reels manufacturing, the company is poised to champion sustainability and circularity in its segment. Through the usage of science-based technology and methodologies to create environmentally friendly products and backed by reputable international certifications, such as the Forest Stewardship Council® (FSC) certification and the Programme for the Endorsement of Forest Certification (PEFC) certification, Weng Meng Greentech pursues sustainable sources as a way to combat pressing environmental disruption.

Focusing on approximately 120 million tonnes of plantation oil palms felled and discarded annually, the company introduced its innovation flagship product, Life Cycle Plus (LC+); as a sustainable material that serves as an alternative to rainforest hardwood while maintaining aesthetic flexibility and robust physical properties. The company aims to salvage the wasted oil palm tree trunks, transforming it into multiple high-value lumber-shaped products for applications in timber, construction and furniture industries. These premium, value-added products ranging from one-layer and multi-layer panels, blockboards, and Batten Laminated core materials are being meticulously crafted and researched to exceed industry standards.

Weng Meng Greentech is also making significant strides in the Mechanical modification material, introducing innovative method to produce value-added Oil Palm Lumber (OPL). This ground-breaking technology, protected by a patented design developed in-house, focuses on a drying and modified surface densification method and system, intending for LC+ products to stand out as a core material for various applications, including composite panels, blockboards, flush doors, and furniture components, thus, expanding the engineered wood sphere.

While there are several success stories locally, there is a dire need to increase renewable raw material consumption. Government stakeholders, such as the Fibre and Biocomposite Centre (FIDEC), has been consistently engaging the timber manufacturers in Malaysia to blend alternative biomass resources into a range of composite products of wood and fibreboard, flooring, wall panels, door stiles and door jambs, as part of engineered wood products. Fibre-filled thermoplastic and thermoset composites from rice husks, coconut trunk fibres, kenaf and oil palm biomass in the form of oil palm trunks (OPT), oil palm fronds (OPF) and empty fruit bunches (EFB) have the commercial potential of high value-added engineered products.

With continued innovation, the engineered wood segment in Malaysia has the potential to uplift the construction and manufacturing industries. To further facilitate investments in the engineered wood segment, the Government offers incentive support and commits to facilitate investors in this highly advanced technology segment to formulate the strengths of our sustainably managed forests, amidst renewable energy inputs, recycling and repurposing forest by-produce in enhancing our sustainability goals.

For further information on the timber industry, please contact the Food Technology and Resource Based Industry Division, MIDA at

https://www.mida.gov.my/staffdirectory/food-technology-resource-based-industries-division/

1 https://www.grandviewresearch.com/industry-analysis/wood-adhesives-market

2 timber-online.net– update 2021/2022

3 sphericalinsights.com, June 2023