This site

is mobile

responsive

A New Shift Factor

IHS Markit, in their analysis that began since 2015 concluded that the crude oil-to-chemicals (COTC) technology is a revolutionary technology advancement in refinery and petrochemical integration, which could double the profit derived from a barrel of crude oil.

Presently, the world is dependent on petroleum products as the primary source of energy, particularly to power vehicles.

However, as technology evolves and environmental awareness increases, the demand for fossil fuel is expected to decrease in time. As the oil and gas (O&G) industry looks for better alternatives, one of them is to create higher-value chemicals from lower value oil.

COTC poses a solution in this regard; when a refinery is merged with a petrochemical plant to become one integrated processing plant, it can potentially bring higher profits to the operators.

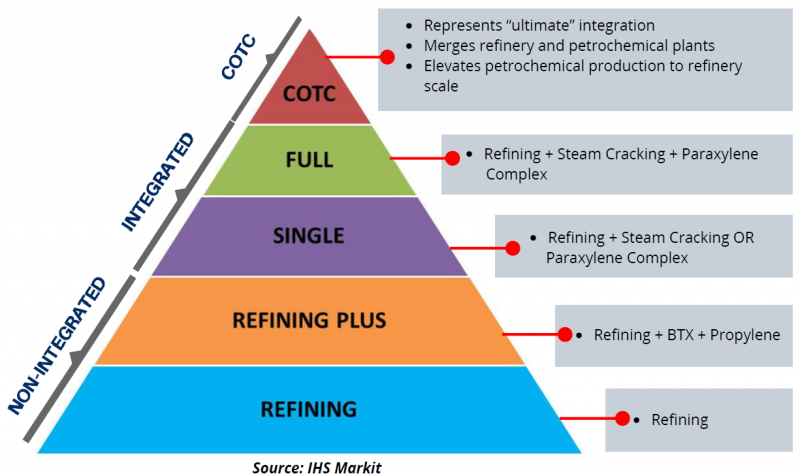

The degree of refinery-petrochemical integration is classified into four (4) levels. COTC is positioned at the top most level of integration as the share of chemicals production exceeds 70 per cent in an oil refinery-petrochemical integrated plant, compared to only 10 per cent in a non-integrated conventional refinery.

The Global Projects Highlight

Given the current volatility of global oil prices, converting low-value oils into high-value chemicals hugely benefits the O&G industry players.

Presently, there are six on-going global COTC projects in China, Brunei and Saudi Arabia. China is way ahead with four (4) crude oil-to-chemical projects.

The table below shows the updates of current COTC projects:

In October 2020, Saudi Aramco and SABIC announced that both companies have decided to re-assess their COTC project, as global oil companies re-evaluate their energy projects to conserve cash flow in the collapse of oil price and demand, hugely caused by the coronavirus pandemic.

COTC Opportunity opens In Malaysia

Based on the BP Statistical Review of World Energy 2020, Malaysia ranks fourth in the Asia Pacific for largest oil reserves; after China, India and Vietnam, with 2.8 billion barrels at the end of 2019. Most of Malaysia’s oil reserves are extracted from offshore fields.

Currently, there are six non-integrated conventional refineries operating in Malaysia with the capacity of approximately 700,000 barrel per day. Given the opportunity in COTC technology, Malaysian refiners and petrochemical players should explore to develop specialised facilities which could convert high-grade crude oil into high percentage of chemicals, as opposed to their current fuel and refined products.

The Malaysian Investment Development Authority (MIDA), as the central government agency for the promotion of investments, acknowledges that the petrochemical industry remains a significant sector for the country.MIDA is defining several initiatives to strengthen the ecosystem of the petrochemicals industry, as it is crucial to attract the right technology providers to revamp and rejuvenate the process structures of petrochemicals complexes to resonate the industry’s future-proofing efforts.

The integrated refineries with petrochemicals complex stand to benefit from the adoption of emerging technologies of Internet of Things (IoT) and Industry 4.0. These enablers will boost the efficiency of production processes to maximise the output of the finished products of higher value chemicals. The Industry 4.0 breakthroughs, among others, may result in the optimum usage of carbon; extraction and inclusion of hydrogen; low emission; smart usage of utilities and optimal capital expenditure.

With attractive investment opportunities, substantial feedstock availability and the adopting COTC emerging technologies, it will be a game-changer for the petrochemicals industry in Malaysia to rise and meet the future global demands.