This site

is mobile

responsive

The evolution of digital printing technologies has revolutionised the industry, enabling faster turnarounds, greater data precision, and more flexible print plate options. Innovations in inkjet and electrophotographic (laser) printing are now delivering high-resolution images, all while reducing waste and driving cost-effective, high-quality production.

Sustainability has also emerged as a core focus, prompting the adoption of eco-friendly inks, recycled materials, and energy-efficient equipment. This shift reflects a broader movement towards sustainable practices, where Artificial Intelligence (AI)-enhanced printing processes are also playing a significant role. Small and Medium Enterprises (SMEs) are embracing environmentally conscious practices such as biodegradable inks, recycled substrates, and reduced energy consumption. Additionally, smart automation is being leveraged to streamline workflows, predict maintenance needs, and facilitate large-scale personalised printing.

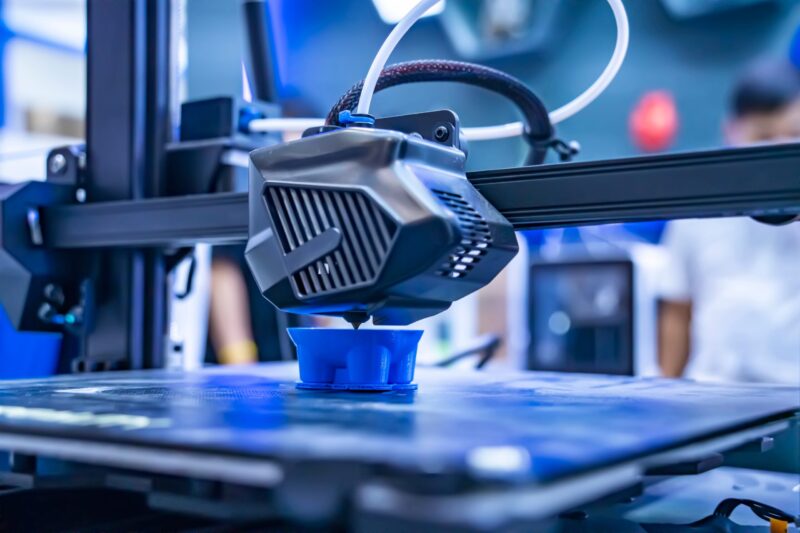

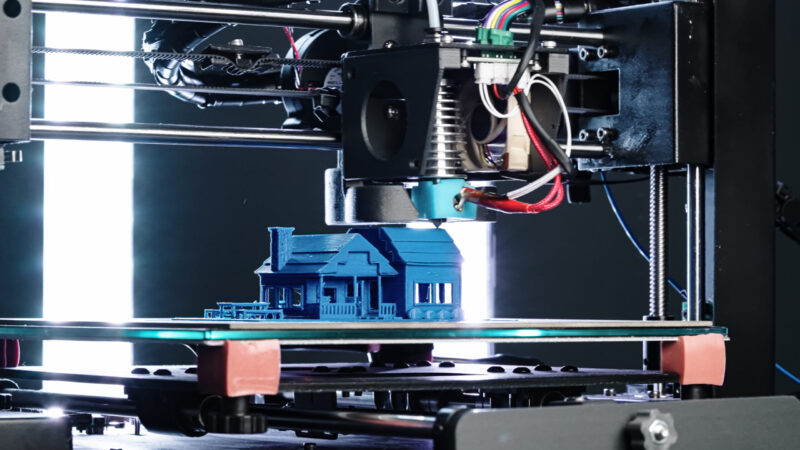

The rapid growth of 3D printing continues to reshape the landscape of prototyping and additive manufacturing. Start-ups across the globe are embracing this cutting-edge technology, leveraging its capabilities to create complex, customisable products. As a result, 3D printing is steadily advancing towards transforming production methods across a variety of industries.

The global commercial printing market, valued at an estimated USD316.58 billion in 20241, highlights the evolving dynamics of the paper, printing, and packaging industries in response to technological innovations and shifting market demands. Since the aftermath of the COVID-19 pandemic, business expansions and market growth have fuelled the rising demand for commercial printing services. This is particularly evident in sectors such as retail, healthcare, hospitality, and education, where printed materials continue to play a vital role in advertising, marketing, packaging, and communications.

The Germans, through companies such as Heidelberger Druckmaschinen AG and Koenig & Bauer, lead the production of high-quality offset printing presses. These companies have modernised the traditional inked image transfer process, where an image is first transferred (“offset”) from a plate to a rubber blanket and then to the printing surface, or through the lithographic method of ink rollers applying ink to image areas on a flat planographic carrier, while water rollers coat non-image areas with a water-based film.

Operations today present advanced continuous ‘web’ process feeds of large reels of paper through large advanced press machines. Offset printing, best suited for economic scale, produces large volumes of high-quality prints in a manner that requires little maintenance. These presses are now linked to Industry 4.0 technologies, using computer-to-aluminium plate systems, replacing the older computer-to-film workflows. Key innovation includes the development of hybrid printing presses that combine offset and digital printing capabilities.

Meanwhile, the 3D printing market is expected to experience substantial growth, rising from USD23.41 billion in 2025 to USD101.74 billion by 2032, reflecting a compound annual growth rate (CAGR) of 23.4%2. The United States holds a dominant position in the 3D printing market, capturing over 30% of the global market share for niche products, excelling in digital printing technologies with industry leaders such as Stratasys Ltd, 3D Systems Corp, and HP Inc.

From the East, China has also made significant advancements in additive manufacturing, with companies such as Xi’an Bright Laser Technologies (BLT), specialising in metal 3D printing, and Tianjin Lim Tech Co., known for sand 3D printing, expanding their operations into Europe and the USA. Metal 3D printing, particularly Selective Laser Melting (SLM), merges the design flexibility of 3D printing with the strength and lightweight qualities of high-performance metal alloys, enabling the creation of unique and durable parts for complex applications. Additionally, the Binder Jetting technology, which uses sand materials such as Silica and Zircon to create moulds and cores, is revolutionising the industry. This process builds parts layer by layer, with a binder bonding and strengthening each layer.

Japanese companies, including Komori, Canon, Epson, and Ricoh, have made significant strides in hybrid printing technologies that combine both digital and traditional printing methods. These innovations are offering the best of both worlds in terms of technology and sustainability, catering to the evolving needs of the global industry.

Reflecting global trends, Malaysia’s printing industry has also evolved to meet local and international demands. The country’s strong economic diversification, fuelled by the rise of Industry 4.0 processes and a growing sustainability focus, continues to encourage commercial printers to invest in eco-friendly raw materials and cutting-edge technology. Such investment is enabling industry players to offer high-quality printing services across sectors such as paper, packaging, labelling, industrial products, advertising, education, retail, and e-commerce.

In line with the objectives of the New Industrial Master Plan (NIMP) 2030, the integration of the Internet-of-Things (IoT) enables printing companies to deliver differentiated, high-value solutions while enhancing real-time monitoring and predictive maintenance. Additionally, the sourcing of sustainable and certified raw materials ensures competitiveness in the global market. The workforce continues to enhance its capabilities in operating advanced machinery and adopting sustainable practices through digital and green printing technologies.

The expansion of smart printing technologies has also sparked increased interest in 3D printing and eco-conscious practices related to energy use and raw material sourcing. New business opportunities are emerging within the supply chains of industrial products, particularly in the consumable sector.

Malaysia also offers strong export potential, especially in premium packaging and advertising solutions for global brands. Between 2020 and 2024, over 200 companies in the paper, packaging, and printing industries with total investment exceeding RM5 billion have been granted Manufacturing Licenses (ML), solidifying the presence of regional players that have established operations in Malaysia over the past 30 years. Prominent companies in the sector include well-known names such as Times Offset, GS Paper & Packaging, Thumbprints UTD, Benkert, Vivar Printing, INTERPRINT Decor, Ean Label Industry, Sanko Sangyo, Hayan Prints, Shin Nippon Industries, Federal Packages, Sanwa Screen, UPM Raflatac, Printelligence, PICO Malaysia, and Percetakan Nasional Malaysia Berhad (PNMB).

Vivar Printing Sdn. Bhd., a Malaysian company that has made significant progress over the past four decades, is now a trusted partner to prestigious international publishers and brands. With a market presence extending across Asia, Europe, Africa, Australia (Oceania), and the USA, the company has grown from a modest single-colour press operation into one of the largest privately-owned printing establishments in Malaysia. This remarkable growth highlights the success that can be achieved through the seamless integration of technology and technical expertise.

INTERPRINT Decor (Malaysia) Sdn. Bhd., a subsidiary of Germany’s INTERPRINT GmbH, is a global leader in decorative surface design and printing, specialising in the production of high-quality printed decorative paper used for high and low-pressure laminates, melamine-faced chipboards, and medium-density fibreboards. Since its founding in 1995, the company has embraced technological advancements, notably adopting industrial digital printing to improve design precision and efficiency. Over the years, INTERPRINT Malaysia has achieved significant gains, including a 2.85% increase in net sales revenue in 20233, underscoring its strong market presence across the Asia-Pacific region, with key markets in Australia, India, South Korea, Thailand, and Japan.

Canon MailCom Malaysia Sdn. Bhd. (CMCM), established in 1982, as part of the Canon Inc. Group, Japan, is leading business process outsourcing for integrated data and document processing solutions. Its services range from data extraction, conversion to document formatting and preparation in transaction printing for both physical and electronic distribution. Optimising technological advancements in Customer Communication Management software and related application developments, CMCM recorded net sales revenue increase of 9.35% in 2023, reflecting its strong market presence and operational efficiency in hybrid printing businesses3.

Pico International (M) Sdn. Bhd., headquartered in Singapore, has been operating in Malaysia since 1982. The company has continuously advanced, evolving from using the latest inkjet printing technology in the 1990s for static exhibition stands to integrating software design and high-tech exhibit production. Today, Pico is recognised as one of the global leaders in exhibition design, advertising, and brand activation. The company utilises cutting-edge technologies such as 3D printing, advanced ‘designjet’ printers, graphic design capabilities, and electro-mechanical expertise to create high-quality, integrated exhibits for global clients. Some of these exhibits are even animated in Virtual Reality environments for event promotions and trade shows.

Malaysia remains at the forefront of adopting cutting-edge technologies to strengthen global partnerships. With its strategic location, well-established logistics infrastructure, and access to globally certified process providers, Malaysia offers competitive advantages for printed products, packaging, and promotional materials, especially for export markets.

The Government’s ongoing support, particularly through the Automated Capital Allowance (Automation CA) programme, plays a crucial role in transforming printing processes and developing talent within the industry. MIDA is committed to assisting printing companies in upgrading to Industry 4.0-based machinery to qualify for Automation CA eligibility.

For further information on this facilitation, contact Food Technology & Resource Based Industries Division at https://www.mida.gov.my/staffdirectory/food-technology-resource-based-industries-division/.

1Fortune Business Insights, 23 December 2024

2Fortune Business Insights, 24 Jan 2025

3emis.com, 31 August 2024