This site

is mobile

responsive

The production process within any factory or operation consists of a system of actions that generally result in products or services that have value to the general public. Many factors govern the set-up of this process – and one important aspect includes the implementation of what is known as Occupational Health and Safety (OHS) issues, which is concerned with the safety, health, and welfare of the people who work in the process.

It means that first and foremost, workers must be kept safe while engaging in their employment, whether it comes in the form of knowledge of their skills and training or safety equipment. The recent COVID-19 pandemic where frontliners were issued with Personal Protective Equipment (PPE) on a frightening scale brought that message close to home.

Fortunately for Malaysia, there is a company that is completely dedicated to manufacturing a broad range of head protection gear with more than a quarter century’s worth of experience. Proguard Safety Manufacturing Sdn. Bhd. is internationally recognised as one of the leading independent Malaysian PPE manufacturers that offers services covering various types of business models including Original Equipment Manufacturing (OEM), Original Design Manufacturing (ODM), and Original Brand Manufacturing (OBM).

While Proguard’s core business is manufacturing a full range of PPE under OEM basics, they are specialists in protective gear for the head, face, and hearing, where their products have managed to combine optimal protection with comfort and style. As such, the company prides itself on being able to offer world-class products as well as all-in-one business solutions for the international markets, where it currently manufactures in 38 countries globally.

Firm foundation to ensure head safety

Proguard was first founded as Meta-Alliance Industries (M) Sdn. Bhd. in 1996 by the husband-and-wife team of Dato’ Lee Ngai Mun and Datin Cindy Choh Yem Mei. With a vision towards becoming the market leader for safety PPE, the founders saw innovation as the main one-stop solution to fulfil global market needs, on top of their own all-embracing need to create a zero-accident workplace environment as much as possible.

Within its first decade of operation, the firm went from strength to strength, winning the Malaysia Good Design Award consecutively from 2001 to 2003 before starting its international expansion in 2004. The year 2008 saw the firm establish a business relationship with the Würth Group, the first of its international collaborations. As a result of these cooperative ventures, the company was able to innovate and create new products, including the Advanrim full brim helmets, the Advanlite lightweight helmets, and the AlpinPLUS mountain climbing-inspired helmets.

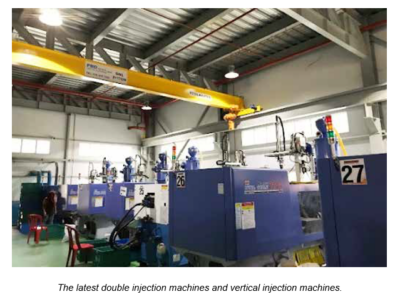

By the time it reached its 21st year in 2017, Meta-Alliance Industries (M) Sdn. Bhd. has decided to move onwards and officially changed its name to Proguard Safety Manufacturing Sdn. Bhd. This change saw the firm upgrade its production area with double injection machines and vertical injection machines – a game-changing strategy that has resulted in the creation of the Hydra line of double injection safety eyewear and the Momentum line of high-impact tested helmets.

Cadex makes its own impact

Proguard made a conscious decision to establish and maintain its own in-house design team and tooling department which specialises in designing and producing moulding for its customers. In addition to allowing for unique and customisable product designs that are exclusive to each country’s target market, it ensures that the designs are of the finest quality in terms of strength and attention to detail.

The firm’s testing lab utilises a rigorous quality assurance (QA) method that conforms to many international test standards, thus ensuring that their products meet as many world standards as possible. Specifically, Proguard prides itself on being the only company in the Southeast Asian region that owns a Cadex impact machine and produces test reports that allow for an accurate and precise representation of impact data.

The testing machine is scheduled for daily calibration before conducting tests, with two different types of impactors used for specific types of testing methods: the shock absorption test, and the penetration test. This is ably supported by software that has been pre-set to every testing standard the company complies within a bid to reduce human error.

Heading into the future

As with the rest of the world, Proguard was severely affected by the pandemic in terms of the cost of materials, products, labour, and supply disruptions. In order to continue to be relevant in the market, the firm decided to step up the diversification of its business model of offering medical PPEs by obtaining recognition by the Ministry of Health’s Medical Device Authority (MDA) as a Manufacturer and Authorised Representative, Distributor, and Importer – covering their full range of medical PPEs from head to toe (including face shields, disposable medical coveralls, medical grade surgical face masks, and isolation gowns).

In response to the labour shortage, Proguard began to adopt Industry 4.0 (IR4.0) solutions and initiatives. This includes identifying gaps in the use of IR4.0 systems for production output data as well as recording the breakdown data of their machinery. On the management side, the firm is also setting up and improving relevant key performance indicators (KPIs), dashboards, and reports to track and demonstrate tangible improvements that can be implemented within their company ecosystem.

MIDA is proud to partner with a local champion that is looking to adopt and adapt IR4.0 technologies to offer significant opportunities for improving both operational and production output. The implementation of these technologies will not only help Proguard to meet the increasingly complex expectations of its customers and increase its efficiency and agility, but it will also help push the Malaysian manufacturing landscape in the right direction for the nation to be viewed as a worthy investment target.